In highly corrosive and chemically aggressive environments, conventional valves often fail to deliver the necessary performance and durability. This is where PTFE lined ball valves come into play. Designed specifically to withstand harsh media, PTFE (Polytetrafluoroethylene) lined ball valves provide superior chemical resistance, reliable sealing, and long service life. These valves are widely adopted across various industries including chemical, pharmaceutical, petrochemical, and wastewater treatment plants.

What is a PTFE Lined Ball Valve?

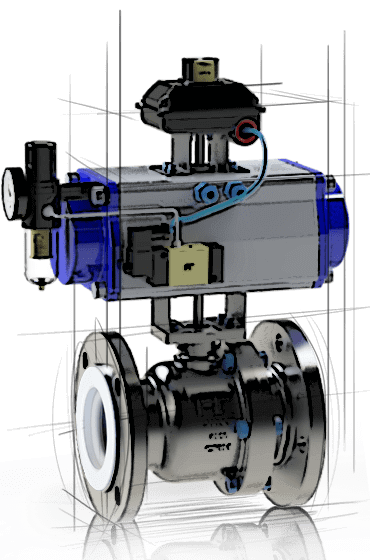

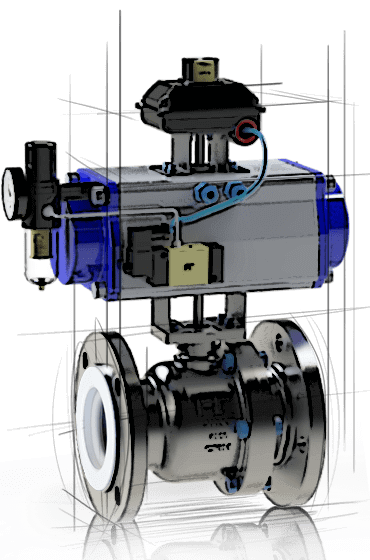

A PTFE lined ball valve is a type of quarter-turn valve in which the inner surfaces—especially the ball and body—are lined with PTFE, a high-performance fluoropolymer. PTFE is known for its exceptional resistance to chemical attack, non-reactivity, low friction coefficient, and ability to withstand high temperatures. The valve structure typically includes a stainless steel or carbon steel body for mechanical strength, while the internal PTFE lining offers a protective barrier against corrosive fluids.

Key Features of PTFE Lined Ball Valves

-

Chemical Resistance: PTFE provides outstanding resistance to nearly all corrosive chemicals, including acids, bases, solvents, and chlorinated compounds.

-

Leak-Free Operation: The soft-seated design and precision-molded lining ensure bubble-tight shutoff, reducing leakage risks.

-

Low Torque Operation: PTFE’s self-lubricating properties allow smoother operation with minimal torque requirements.

-

Wide Temperature Range: These valves are suitable for operations ranging from -20°C to +180°C, depending on the process fluid and pressure.

-

Full Bore Design: Most PTFE lined ball valves come with a full port or full bore, ensuring no pressure drop and easy pigging where required.

-

Fire Safe and Anti-Static Design (available in select models): Enhances safety in explosive or flammable environments.

Applications Across Industries

1. Chemical Industry

In the chemical processing sector, handling aggressive acids and bases is routine. PTFE lined ball valves are ideal for these applications due to their chemical inertness and corrosion-resistant properties. Whether it’s sulfuric acid, nitric acid, or caustic soda, these valves ensure long service life without degradation.

2. Pharmaceutical Industry

PTFE lined valves play a crucial role in the pharmaceutical water system, as well as in fluid handling systems involving solvents and process chemicals. Their ability to maintain product purity and withstand frequent sterilization processes makes them indispensable in cleanroom environments.

3. Food and Beverage Industry

PTFE is FDA-approved, making these valves suitable for food-grade applications. In beverage production and food processing, PTFE lined ball valves are used for handling flavoring agents, cleaning fluids, and other reactive ingredients without contamination.

4. Water and Wastewater Treatment

In water treatment plants, valves are exposed to chlorine, ozone, and other disinfectants. PTFE lined ball valves provide corrosion protection and reliable sealing even under continuous operation in such chemically intensive environments.

5. Petrochemical Industry

For transferring hydrocarbons, amines, and other corrosive compounds, PTFE lined valves offer a safe and durable solution. Their anti-static and fire-safe variants make them suitable for hazardous zone installations.

Advantages of Using PTFE Lined Ball Valves

-

Extended Service Life: The non-reactive PTFE lining significantly increases the valve’s life span in aggressive environments.

-

Cost-Effective Solution: Though slightly higher in upfront cost, the reduced need for maintenance and replacement makes these valves economically viable over time.

-

Environmentally Safer: By minimizing leakages and material degradation, PTFE Lined valves help industries comply with environmental safety norms.

-

Customizable: Available in a variety of sizes (15mm to 300mm), pressure ratings (Class 150/PN10/PN16), and actuation options including manual, pneumatic, and electric.

Conclusion

PTFE lined ball valves are engineered to provide exceptional performance in demanding industrial environments. Their robust construction, superior sealing, and unmatched corrosion resistance make them a preferred choice for fluid handling in critical applications. From pharmaceuticals to chemicals, these valves serve as a reliable link in maintaining process efficiency and product integrity.

For industries seeking precision-engineered, high-quality PTFE Ball valves, Freture Techno Pvt. Ltd. stands out as a leading manufacturer in Mumbai, India. With a commitment to innovation and quality assurance, Freture Techno delivers customized valve solutions tailored to diverse industrial needs.